IT IS usually said that a typical narrowboat needs about 2kW to keep it comfortable in cold weather, although more is obviously needed to heat it initially. Energy (and therefore cost) can be saved by reducing losses, utilising waste heat and/or installing a more efficient system. Malcolm Bridge, IWA Sustainable Boating Group, gives us more information…

Reducing losses

Most narrowboats have a nominal 1in of insulation on the cabin sides and roof and 2in on the hull. Some also have underfloor insulation. In older boats it will all be polystyrene or polyurethane foam slab.

Newer boats have spray-foam on the sides and roof with slab foam, if anything at all, under the floor. Spray-foam is far superior if applied properly. However, controlling its application is difficult and there are reports of skimping to minimise the cutting back required. Its thickness should therefore be checked before it is covered.

Such insulation is adequate for two-season use but barely so for boats used all year round, particularly those serving as homes. Unfortunately, higher performance alternatives are so expensive that increasing foam thickness is really the only affordable option despite its impact on interior space.

Even this is viable only in new-builds and during major refits as upgrading existing insulation requires extensive reworking of panelling. Anyone considering buying a boat should therefore ensure the adequacy of its insulation before proceeding.

Double glazing a new build is clearly worthwhile, though retrofitting is not cost-effective unless existing windows need to be replaced for other reasons. Units with ‘warm-edge’ spacers insulate better than conventional ones, although failure rates are high as the spacer needs (but often doesn’t get) careful handling prior to assembly.

They can also be visually obtrusive as the spacers don’t take shaping as well as their aluminium counterparts. Vacuum glazing units insulate very much better but are considerably more expensive still.

In designing a boat from scratch, configuration is therefore a potential energy-saving factor for consideration: a tug, for instance, will enjoy the lowest heat losses via windows, while providing the greatest security.

Using waste heat

As much as 90% of the energy in propulsion fuel can finish up as waste heat in either the engine coolant or exhaust. Recovering heat from the latter is difficult but using coolant to heat domestic hot water is well established and more is available for space heating.

Interfacing engine cooling and heating circuits, using a heat exchanger, can fully supply radiator-based systems whenever the engine is running but, as running engines while moored is uniquely wasteful, a back-up system is needed. Non- or rarely cruised boats should, therefore, not rely entirely on such a system.

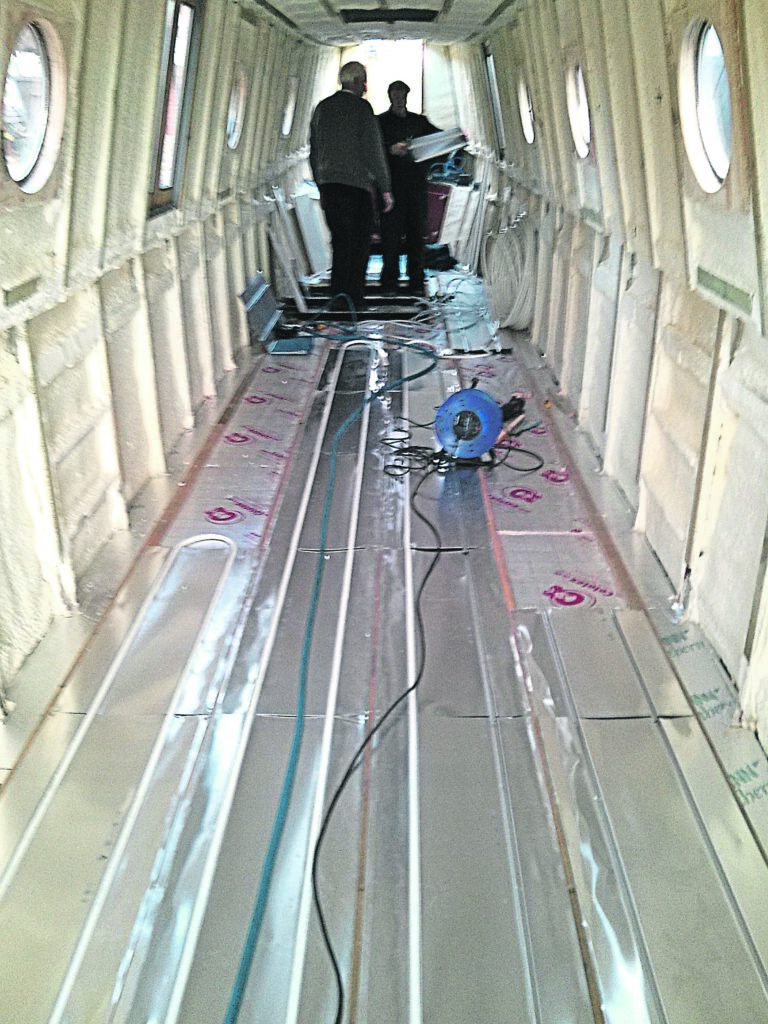

If there is room for a second calorifier, heat can be stored for later use, though making the best use of it requires a system which operates at a lower temperature than radiators, the best known being underfloor.

However, as installing this is only viable in new builds, the amount of heat that can be stored is limited and boats have insufficient exposed floor areas for underfloor heating to be adequate on its own, so a back-up system is still necessary. Replacing existing radiators with fan-assisted ones, which are also effective at lower temperatures, is probably the easiest retrofit option.

More efficient heating

The only more efficient heat source available is a water-source heat pump. These use power to move heat rather than produce it, thereby delivering more heat than the electricity they consume.

A Coefficient of Performance (energy out/energy in) of 3 is typical for air-source pumps, but water-source ones can achieve a coefficient of 4 or 5 as water is a better heat source. Recovering heat from waste water, which is warmer than that in the canal, can enhance performance.

As their optimum output temperatures closely match those required by low temperature heating systems, there is a natural synergy. That said, a heat pump could still use up to 8 kWh/day, only likely to be available on an electric-drive boat with a large battery bank though, combined with the savings discussed elsewhere, can probably halve this.

The most energy-efficient heat delivery system should be (wet) radiant ceiling heating in which the ceiling, at 30oC, radiates heat downwards, warming people and objects directly, with limited heating of the air.

As a result, heat losses, which depend on the difference between internal and external air temperatures, are reduced, typically by 20-25%. Moreover, as boats have larger exposed ceiling areas than floors, a ceiling system can potentially heat a boat fully. Combining ceiling and underfloor systems is also an option. Now what is needed is someone to try it!